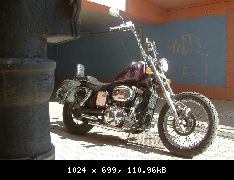

Why I did started modifications?

Well, I always wanted to have a bike with high handlebar ;) Besides, Mobster had following defects:

- no reseve (and I had to push this heavy bastard to the gas station twice)

- a little mess in wiring harness

- gear shifing rod made from rusting iron

- open cooling system, because of which in traffic jams cooling fluid was boiling

- veeery weak brakes

So, let's get to the work ;)

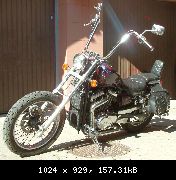

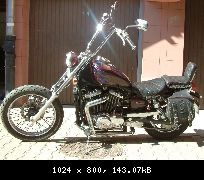

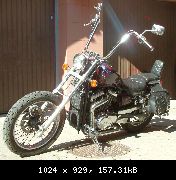

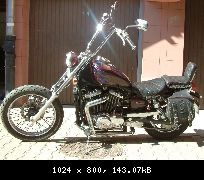

List of visible modifications:

- High handlebar (ape hanger) Highway Hawk

- Wiring inside of handlebar

- Gears shifting rod made from inox steel

- New rear turn signals

- Saddlebag supports

- Driver footpegs moved 4cm to the sides

- New chrome headlight with visor

- Leather grips with chrome ends

- Steel brake line

- Two-piston caliper from GS 500 (much better brakes)

|

|

|

|

List of invisible modifications:

- Cooling system modified from open to closed (original parts from VZ 800)

- Electric driven fuel cock (my own idea :) )

- Reinforced gas lines (they look like rope)

- Fixed wiring harness

- Relays to minimize voltage drop

- Open air filter

- re-jetting using Factory Pro set (bike acquired much more power with moderate

increase of fuel consumption)

|

|

Remarks:

- Highway Hawk handlebars are relatively cheap, but have some disadvantages.

One of the problems is that this handlebars do not keep cross-section profile

on bents. The next problem is that the holes, that according to description

should be for cables are in weird places and have small diameter (6mm).

I think that someone made strange mistake writing that holes for cable holders

are holes for cables. Material for handlebar is a little bit too soft.

- Wiring in handlebar: to provide all the required signals, I needed multicore

cable. I made 8mm holes in handlebar; for this diameter I was able to insert

5-core 1mm2cable - a little bit too small. I've decided to add relays

and for handlebar wiring I used YTKSY 7x0,5mm2 cable. Such cable is able

to carry 4A safely, so I installed relays for:

- lights (1 pc, switching between HI/LO)

- turn signals (2 pcs)

- brake light (1 pc)

- horn (1 pc)

Whether there is a need to use relay for horn - it's moot problem, but as it's

inductive element, so thin cable could cause high voltage loss and heat emission.

Clutch switch, engine top switch and starte button were connected directly

using 0,5mm2 cable - it's enough.

In the begining, relays were under frame neck, but then I made small circuit

with microrelays that fit inside headlamp.

- If you plan to thread inox steel, buy robust die. Weak tools could loose tooths

or even could break in half.

- Cheap saddlebag support for Savage available in Louis shop does not guarantee

trouble free installation. According to manual, in the front it should be installed

over fender strut, in the back - below it. The problem is that strut is 20mm wide,

but saddlebag support mounts are in one plane. Installation is possible, but not

easy.

- Electric driven fuel petcock - I had no original petcock, so I used two

electric driven fuel valves and a switch. I used two way switch, but three way

switch could also be used and in the middle position fuel would be cut off completely

- simple anti-theft protection.

|

|

|

|